[Part 1 of a continuing series on Bull Stockwell Allen’s approach to building innovation.]

Sustainability – both environmental and financial – is one of the core principles Bull Stockwell Allen brings to each of its projects.

That means that from the moment we commence a project, we keep in mind the need for sustainability, from the core concept, to the design of building systems, and to the construction of the building itself.

In particular, we’re mindful that the construction process, as currently configured, is incredibly problematic for the environment in terms of energy used, waste, and even the impact on human lives.

According to the US Green Building Council, the construction industry accounts for 40% of worldwide energy usage. Building material, such as concrete, aluminum, and steel, are directly responsible for large quantities of CO2 emissions due to high contents of embodied energy content, with 9.8 million tons of CO2 generated from the production of 76 million tons of finished concrete in the US. Construction activities consume half of all the resources extracted from nature and account for one-sixth of global freshwater consumption, one-quarter of wood consumption, and one-quarter of global waste.

If the effects on longer-term global warming weren’t enough, there are more immediate life-safety issues: a pile of construction debris caused a landslide in Shenzhen, China that killed more than 70 and displaced 900 others. The slide also demolished a host of buildings, including 33 factories, workers’ living quarters, and apartments.

Waste and resource depletion are also economic matters. Governments are becoming more stringent in their regulations, and waste is exactly that: unused, unneeded resources that were still paid for in some form. And investors large and small are increasingly evaluating their investments on the basis of ESG principles (environmental, social, and governance) goals and looking to invest in compliance with the United Nations’ Sustainable Development Goals (SDGs).

But the architecture and construction industries are fighting back. We’ll keep shining the spotlight on these, but here’s one of the trends we’re following closely. First up: Mass Timber.

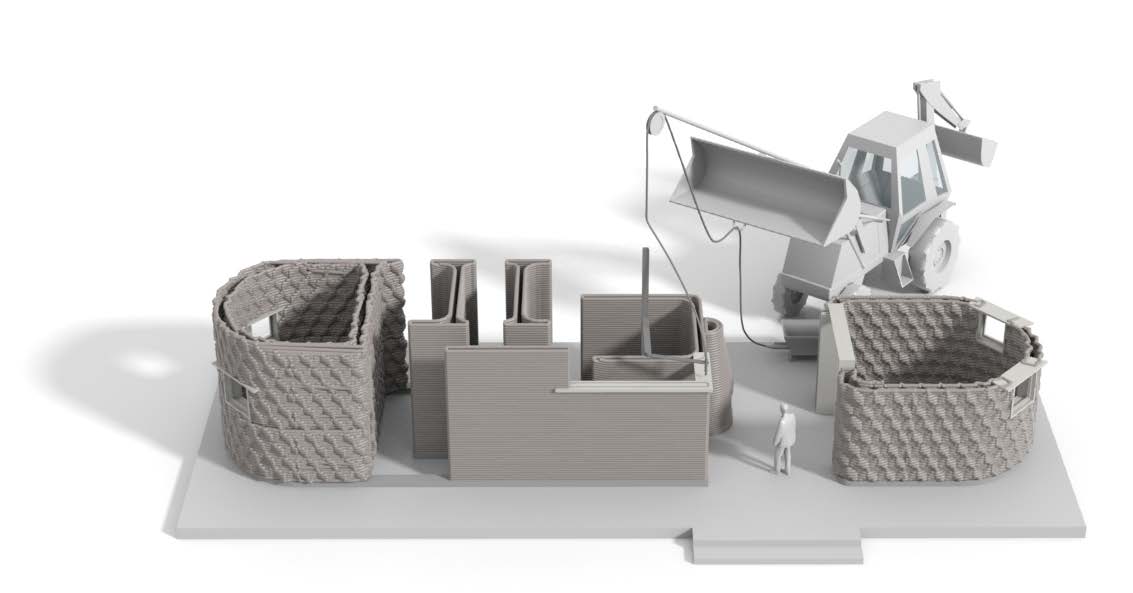

Mass timber refers to the use of cross-laminated wood panels in construction, instead of steel and cement typically favored today. It uses large solid wood panels, typically panelized and engineered, for wall, floor, and roof construction. It uses cross-laminated timber panels (CLT panels), which consist of layers of lumber that are oriented to one another and then glued together to form structural panels. In addition to CLT panels, another material used in mass timber construction is nail-lamented timber (NLT). NLT is made by layers fastened together with nails or screws, and it is commonly used in floors and roofs.

Mass timber is increasingly accepted in commercial construction: according to the New York Times and Katerra, a construction company, as of September 2020, there are 384 large mass timber buildings in the US with another 500 either in construction or under development. And it’s being used in larger and larger buildings: a 25 story residential building is under construction in Milwaukee. Even the ever-thrifty Walmart is using mass timber in the construction of its new headquarters. And hotels using mass timber in construction are under development in British Columbia and Austin, TX

Proponents of mass timber cite numerous reasons to expand its use.

- Mass timber is sustainable: By some estimates, the near-term use of cross-laminated timber and other emerging wood technologies in buildings 7-15 stories could have the same emissions control effect as taking more than 2 million cars off the road for one year. The Journal of Sustainable Forestry calculated that a 14% to 31% reduction in global CO2 emissions could be realized by substituting wood for concrete and steel in building and bridge construction. While some commentators have worried about the impact of increased timber use on deforestation, Katerra engineers say the average diameter of trees used for panels is 12 inches, which makes them just the sort of small trees that foresters say need to be thinned from forests to curb wildfires. (Old-growth trees – particularly at risk of overuse in design and construction – are not used in the production of cross-laminated timber.)

- Mass timber is fire resistant. Unsurprisingly, the mass timber industry has conducted significant testing on the material. As numerous high rise fires have shown us, steel is not completely fire resistant and will fail at high temperatures. According to testing, mass timber – because of its construction – behaves differently from conventional wood and steel: it chars but doesn’t catch on fire, and is often self-extinguishing. During a fire resistance test of a 5-ply cross-laminated timber (CLT) panel wall, the panel was subjected to temperatures exceeding 1,800 Fahrenheit and lasted 3 hours and 6 minutes, far more than the two-hour rating that building codes require. Some municipalities are still resistant to its use, though that’s starting to change, as well. As any homeowner knows, however, wood is susceptible to insects and moisture. It’s imperative that architectural and construction detailing is sound.

- Mass timber is lightweight but strong. Recent mass timber buildings weigh approximately 1/5th that of comparable concrete buildings, which in turn reduces their foundation size, inertial seismic forces, and embodied energy. This is particularly important in areas prone to earthquakes: High strength-to-weight ratios enable mass timber to perform well during seismic activity.

- Mass timber can be surprisingly cost-effective. Mass timber buildings are roughly 25% faster to construct than concrete buildings and require 90% less construction traffic. Since mass timber panels are prefabricated offsite, and then assembled on-site, buildings made from mass timber typically have shorter project timelines and safer construction sites.

The use of mass timber is not an either/or proposition. It can also be used in combination with more traditional “modern” construction techniques without significantly compromising sustainability: for example, a SOM report on wood construction found that hybrid systems can still save 60 to 75 percent of carbon emissions compared to a concrete-only building.

John Ashworth, Managing Principal, points to BSA’s long history in featuring and honoring wood in its designs. “We’ve long understood the aesthetic and sustainable characteristics of wood. Our signature buildings draw from a design philosophy founded on honest structural expression. In our early days, the firm patented a waterproof roof decking system with the National Redwood Association. In our recent resort residential projects, we are currently combining fire-resistant wood post and beam construction with efficient wood panels that streamline the construction schedule and minimize waste. Our research into mass timber represents the next logical extension of Bull Stockwell Allen’s expertise in heavy timber building solutions.”